Cody Wilson has a goal, a goal to make firearms free. Not free of charge, but available to everyone — if they own a Ghost Gunner. The Ghost Gunner is specialized CNC-milling machine designed to churn out firearms.

The spirit of a 1911. (Photo: DD)

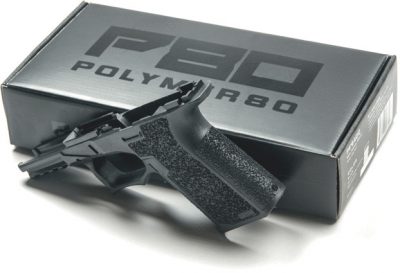

When the original Ghost Gunner was launched it was an AR-15 receiver machine. With this update Ghost Gunners can now produce ARs, of the -15 and -10 variety, as well as 1911s and Glock-compatible pistols.

Why? To prove that you don’t need specialized knowledge to make your own guns. That in-home manufacturing technology has rendered gun control worthless. And also, to make a little money.

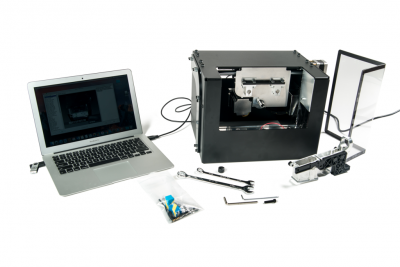

The Ghost Gunner itself is a desktop-sized CNC machine. (Photo: DD)

While the Ghost Gunner is free to operate, it’s not free to own, with a $1,675 sticker. The machine takes 80 percent receivers, which Wilson also sells, and completes them into 100 percent firearms.

Building compete firearms from 80 percent kits isn’t anything new. People have been doing this for decades. What’s different here is that the Ghost Gunner is an automated, turn-key process.

An 80 percent firearm is just a gun-shaped hunk of metal. It doesn’t fire, it has no moving parts; it’s a paperweight. A 100 percent firearm also doesn’t do much — it’s still just a single hunk — but it can be completed with off-the-shelf parts. Only the receiver counts as the “firearm” by ATF standards. Everything else is replaceable and can be bought over the counter.

Up until now the Ghost Gunner could only make rifle-based guns. These can be compact but they’re hardly concealable. Wilson is taking a major step toward democratizing gun ownership now that the machine can make Glock- and 1911-pattern pistols.

It takes a little skill to build a gun out of a firearm receiver, but nothing that can’t be accomplished with time and practice. This is particularly true for Glock-pattern guns, which are designed to use interchangeable parts. Because these use standard and aftermarket gun parts, these homemade guns can be just as well-made or better-made than common factory-produced firearms.

See Also: California Lawmakers Respond to San Bernardino in the Most Illogical Way

It can now complete Polymer80-brand Glock-compatible frames. These are the most popular handguns in use today. (Photo: DD)

The Ghost Gunner and 80 percent receivers are all available through Defense Distributed. Wilson first made headlines in 2012 with the Wiki Weapons Project. Defense Distributed was first set up as a hub for 3D-printed firearms manufacturing.

Defense Distributed only operated in its original capacity for a few months before getting shut down by the State Department. Since then Wilson and his company have been in legal battle after legal battle with their case now waiting before the Supreme Court.

The Ghost Gunner started out as a side project after the Wiki Weapon project was suspended. But even though it’s expensive it furthers Wilson’s original mission. For a couple grand you can get a gun — rifle or pistol — no questions asked.

The term “Ghost Gun” was famously coined by anti-gun California senator Kevin De Leon (D). Leon is leading the charge in attempting to ban the private manufacture of firearms.

It’s legal for anyone who can own guns to make guns, at least on the federal level. It’s even legal to sell or transfer these guns, as long as they aren’t made with the intent of selling or transferring them. They don’t have or need serial numbers.

Does that really make them untraceable? Privacy, by it’s nature, is not meant for prying eyes.

While I used to have a FFL I was diagnosed with terminal Lou Gehrig’s disease. I am looking at buying a ghost gunner. I take it there was a number 1 version. Was it any good as compared to the 2nd version. I have seen a few number 1s for sale for a lot less. I ordered a 1911 80% frame from them. I have not looked yet but there must be hundreds of sites that will tell you everything you need to know and as many YouTube videos showing you how to do it.

I have one and only one goal and that is to find something I can do or think about and get my mind off of my fate. One major concern is the legal side of all this. There is nothing worth breaking the law and facing the ATF. I would like to make some of them and see what I can do to it when it comes to the visible aspect of them as I don’t think you can really improve on the design basis. I could go onto gunbroker and buy several beautiful 1911’s for the money I will spend on this venture. I am buying time off from my thoughts of what is coming. I thought I would like to learn how to do it and if they put a limit on how many you can finish I would just demilled them even if they work or don’t work. So if anyone can help me out with information only on the process and help me build a check list on what items I need to buy and then the way you use the machine. I bought the plans for the same thing on a Norden bomb sight. But being an expert on Norden bomb sights it was way over my head. No legal issues just is there are no spare parts for a stabilizer so I could make hundreds of them and make a fortune but lacked the smarts for a job that job.

I am sure the ATF watches these sites and to them I say no problem as I have no intent on breaking any laws.

Dave

So… would there be any legal ramifications if you owned this machine to renting out to friends and family or anyone else you trusted? They would presumably take the machine, use it, bring it back and pay you for its use.

How about if you rent it to someone so they can use it while it’s sitting in your garage? Get them to sign a rental agreement so there is no confusion about who is finishing the receiver.

How much help could you provide to the person renting the machine while it is being used in your garage?

Could you sell them an unfinished receiver you just happened to have?

What about other gun parts you you just happened to have?

You could have “classes” where folks, for a single fee, itemized of course so the rental fee is separate, could get parts and instruction to have a completed firearm by the end of the class. (For educational purposes only.)

Done right, if this rental scheme is legal, it seems that maybe a guy could turn a buck or two – not that I’m at all interested.

No go on the build party style setups .

I own a decent size machine shop that specializes in gun and gun components. We hold a FFL and SOT manufacturing license which allows us to make full auto weapons up to 50cal. Sometimes we sub contract components to larger companies, but mostly make and sell components for our own company Kineti-tech.

You CANNOT make and sell firearms (serial numbered portion) WITHOUT a type 7 FFL. If you buy this machine you will ONLY be able to make or finish your receiver for YOURSELF…..PERIOD. Some states still also require you to “register” and obtain a serial number for said gun. I do believe you are also legally allowed to make a few per year even it it’s for yourself. This keeps people from building an arsenal that might be used for something else or resell.

Just check the laws with ATF before going and buying a Cnc machine to make firearms. If you do call the ATF make sure you tell them you do have or have access to a Cnc machine to manufacture ….they may tell you that you can’t do it at all without FFL.

I can’t find any reference about being able to make a ‘few’ for your self.

The way I read things, is you can make a gun for yourself. But not for a business venture.

I don’t read the definition of them as being one, or two, or a bazillion.

Can you link to where the information comes from? Or is it an opinion?

No cap just gun shop bs

You can read a review & comments of what a few actual users think of the GC2. You can complete 80% lowers for far cheaper than the price of the GC2. However, if you plan on churning out a lot of firearms for yourself or you if you just like gadgets/new toys it might be worth considering.

1. You cannot use this machine to make firearms to sell without a manufacturer’s license. so none of this “make a little money too.” Yes, there’s an exception: as long as you build for your own use, you are not a manufacturer, and you can occasionally sell a gun if you grow tired of it. But you have to serialize that gun before you do, and if you start selling any appreciable number, expect a visit from the ATF.

2. In California, you are required by a law that went into effect this past January to apply to the Ca.Dept of Justice for a unique serial number, which entails a background check, and you are required to inscribe that number (to the same standards the feds require of manufacturers) on the receiver, along with your name, city and state, before you start milling.

3. It would have been really nice if the article listed the cost of the unfinished lowers, plus the “usual” cost of the components needed to finish it. Because I suspect that you aren’t saving a whole lot of money to “roll your own,” and probably spending a lot more when you figure in the cost of the machine. A quick run through Brownell’s suggests a cost north of $700 for the parts for a Glock build. Who is going to want to pay $800 or more for your “Glock” homebuild? With no warranty? Not me!

it’d be interesting if they offered a glock metal 80% frame

Mark N.- with all due respect, I believe Cody addressed at least one of your concerns on Tom Gresham’s Gun Talk last Sunday. IIRC, Cody said the machine can serialize the receiver. Regarding the California mess, there’s nothing a human being can do about that. Regarding a Glock build, may I humbly suggest that if you were to take a Glock armorer’s course, you’d see how easy it is to maintain the pistol and perform your own warranty work. It’s what I call a ballet in simplicity, the Glock.

I own a machine shop with all modern CNC equipment and I don’t machine receivers. There is a lot more to it than just putting a block of material in a machine and hitting the button!

To own a ‘real’ machine shop and NOT use it for that purpose from time to time is a real loss. If I had what you claim to have, I would be enjoying those machines for the simple fact that they do not pay for themselves, and the more use of them you make = faster recoup on your part. Then you can get to making the big bucks. Who can pay off a mid range cnc without some serious coin.

I also own a small cnc shop, I have turned a couple 80 percent lowers into my own guns, yes it is as easy as loading a 80 percent receiver and pushing the go button, to make a receiver from a forging or a billet is more then just pushin the go button but we were only talking about the 80 percent receivers here